Think Tank

Mapping the Reverse-Logistics Supply Chain

Reverse logistics has become a prerequisite for businesses dealing with connected in-field assets that are managed by service-based contracts. But many have yet to master the complex process, which is directly linked to an organization’s profitability.

Following is a three-step strategy for building a mature reverse-logistics engine. Only in this way will businesses unlock the full potential of the internet of things (IoT), and gain a competitive advantage.

Standard parts management and logistics are customary processes for most manufacturers, but reversing the supply chain can pose complex challenges. Reverse logistics isn’t the same today as it was five years ago. Customer demands and business needs have evolved, and new technologies and channels for delivery have layered further dimensions on the process. Staying ahead of the reverse-logistics maturity curve requires manufacturers to ensure they are maximizing efficiency, reducing costs and decreasing downtime for customers.

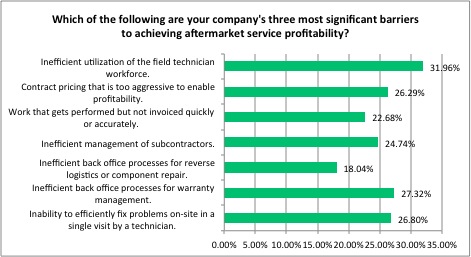

Today, servitized business models are enjoying widespread adoption across asset-intensive industries, but research shows that a fifth of respondents consider inefficient reverse logistics processes to be the main barrier to achieving aftermarket service profitability.

Figure 1: The Impact of Reverse Logistics on the Bottom Line

Reverse logistics must work in harmony with other performance areas such as warranty management, contract management and field service operations in order to cause a positive ripple effect across the entire business. Research suggests top-performing service organizations have embraced this as their modus operandi—and this could apply to manufacturing organizations moving into aftermarket service contracts. There are three steps they need to take to ensure success.

Understand your logistical map. Mapping reverse-logistics operations means developing a full picture of the different ways by which parts and assets move between customers, business systems and warehouse locations.

Effective mapping and managing the need for parts, anticipating or planning returns and the corresponding depot service can transform reverse logistics from cost driver to a revenue-producing business function. This requires reverse-logistics activities to be handled in a unified, standardized fashion, with returns, depot repairs and part or asset swaps all coded in the same language.

Manufacturers should ask the following questions to discover their unique reverse-logistics sequence:

- Where do items go when they leave the customer?

- What sort of items pass through the supply chain?

- Are full assets or parts being returned, exchanged, or simply in need of repair?

- Are pieces managed by entitlements, by warranty or contract?

- How do items get to their destination?

Extend IoT connectivity beyond serviceable assets. There are several areas where the IoT can enhance reverse-logistics operations, beyond parts management. For example, when a customer needs a product or asset swap-out, but the depot is out of the appropriate asset, IoT systems across the organization might show that a truck’s inventory includes a refurbished asset of the same type, or that there’s one freshly repaired at a local shop.

Sharing real-time location information gleaned from the IoT with the customer during the repair stages can also help manage expectations and understand downtime. To create sufficient conditions for this, companies need to have systems in place that provide visibility over parts and asset inventory, and measure performance, even if tracking is managed by a fulfillment partner. Having this information and acting on it could save money, time and improve customer satisfaction.

Pick the right software tool for the job. Visibility is key to managing customer expectations and understanding downtime. To create the necessary conditions, companies need systems that provide a 360-degree view of parts and asset inventory, and measure performance.

Manufacturing organizations can’t compromise operational integrity and disrupt business processes when upgrading to more mature reverse-logistics software. A specialized and sophisticated solution will deliver dedicated reverse-logistics capabilities, organize a firm’s unique complexity, and provide full visibility over every piece of the service puzzle — without muddling internal functions.

Effective asset- or product-based reverse logistics can turn a manufacturing organization into an end-to-end steward for customer needs. But managing a complex supply chain requires keeping up with the modern standards of reverse-logistics maturity. Only when manufacturers map out business needs effectively and make the right hardware and software choices can they turn a complex process into an asset for long-term success.

Tom DeVroy is senior product evangelist at IFS.