Think Tank

Here's What a Post-Covid Supply Chain Review Looks Like

Organizations have faced a slew of challenges in the past year, from material shortages to logistics bottlenecks and volatile swings in demand. More than 90% of Fortune 1000 companies say they’ve suffered supply chain disruptions, according to a report by accounting firm KPMG LLP.

Now, many businesses are reexamining their supply chains and looking for ways to increase efficiency, productivity and resilience.

Total Reboot

Organizations have started to recover from the major disruptions due to the pandemic, but supply chain leaders have no intention of resorting back to their old ways with their supply chains lacking visibility and resilience.

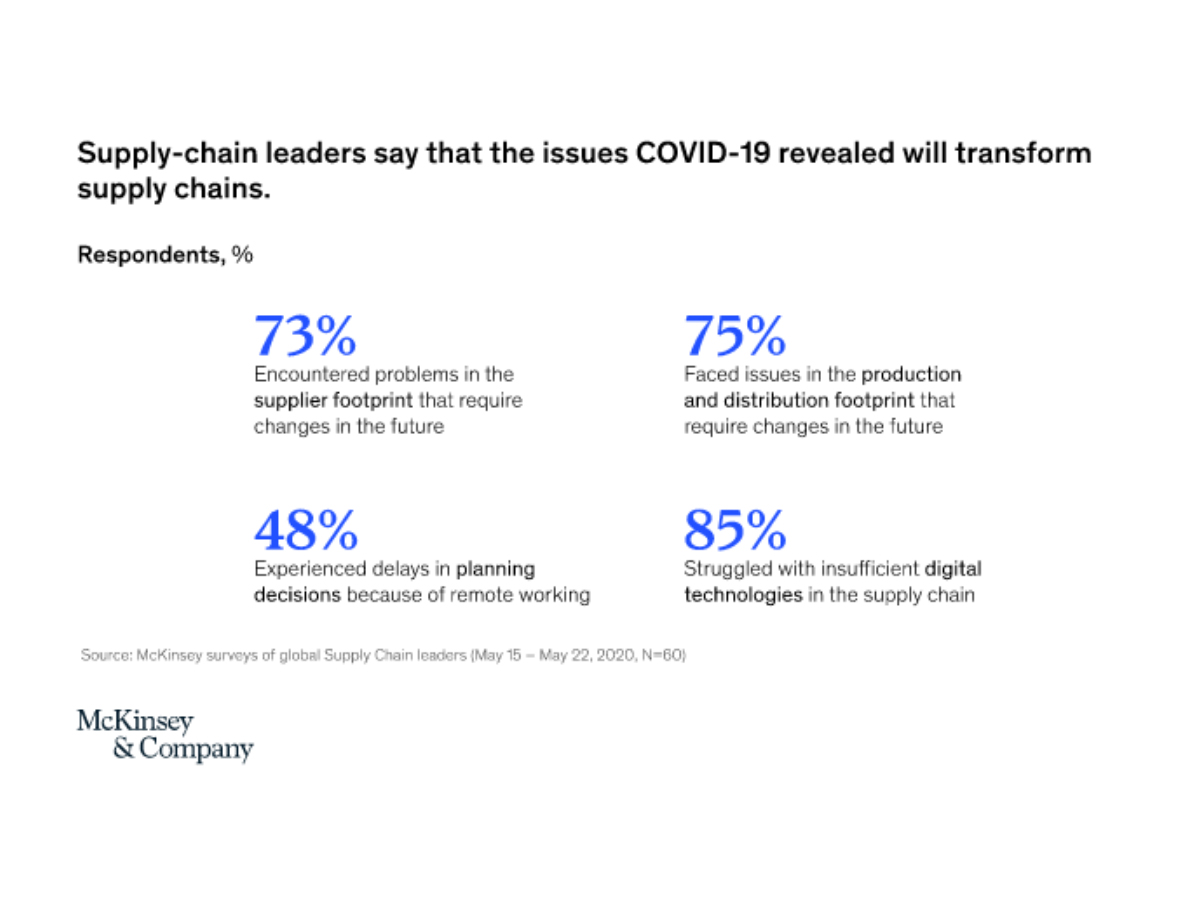

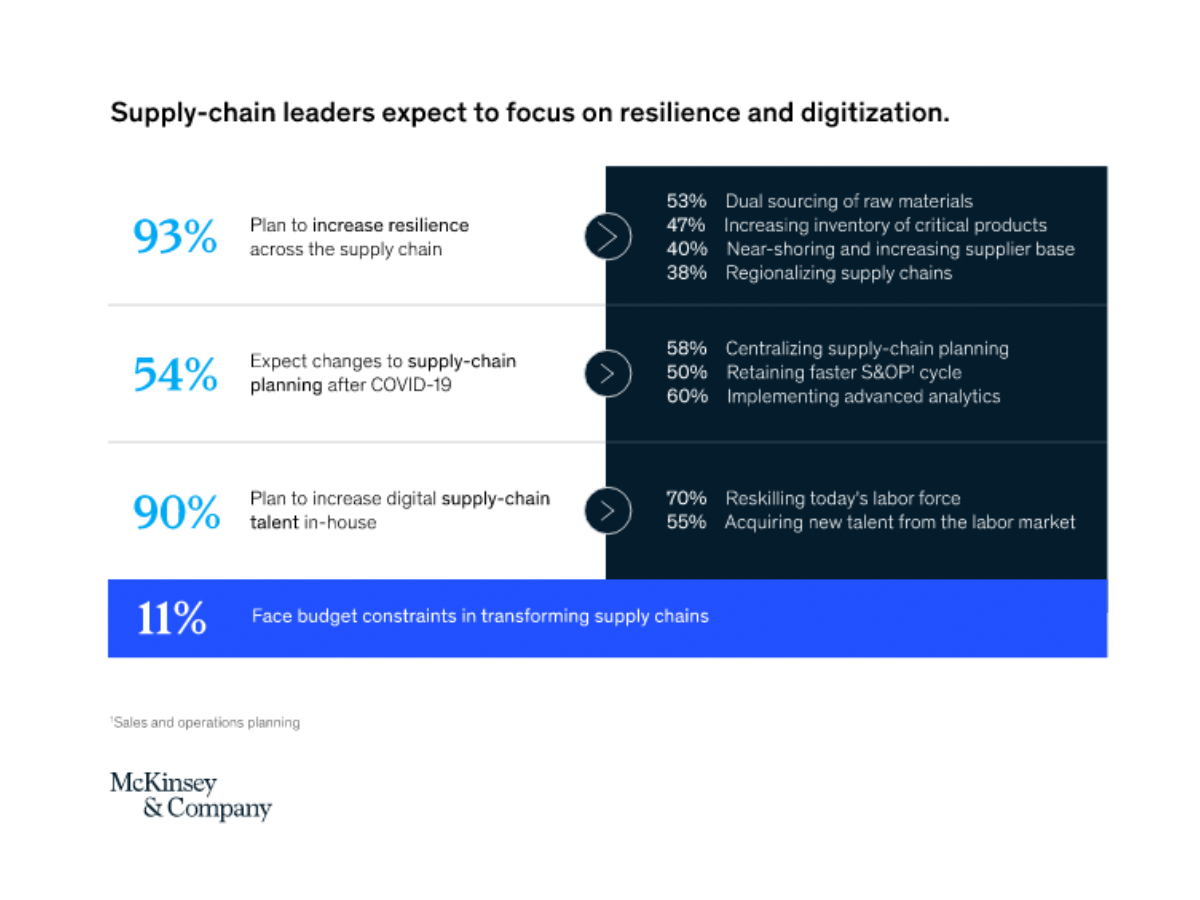

In the second half of 2020, McKinsey & Co. surveyed 60 senior supply chain leaders from a variety of industries around the world. The survey asked how the pandemic impacted their operations and future strategies to make their supply chains more flexible and agile. Here are the responses:

Despite the negative impacts and disruptions, the pandemic has given enterprises an opportunity to revamp and vastly improve their supply chain. This is a direct result from the pandemic greatly magnifying the problems with many organizations’ supply chains resulting as a catalyst to implement the necessary changes.

It's important now to focus on the customer-centric, data-powered, digital technologies that many companies have been slow to adopt due to legacy system compatibility issues and fragmented efforts.

The future success of supply chains will depend on a strong, purpose-built strategy that encompasses several key areas:

- Human resources (HR). It’s necessary to keep updating the skills of workers to keep up with the changing dynamics of the digitized supply chain, improving resilience.

- Regulations. Staying up to date on industry regulations helps to address risks in the supply chain.

- Service delivery model. Optimize service delivery by aligning processes with industry centers of excellence.

- Technologies. Advanced technology solutions can provide complete visibility into the supply chain and end-to-end automation. Examples include automation, smart tracking, predictive analytics, blockchain, the internet of things and machine learning..

- Performance indicators and real-time data. Tracking KPIs with real-time data quickly identifies any weak areas.

It’s helpful to break down a supply chain’s external and internal components into focused improvement areas. To get started, here’s a comprehensive list.

Demand

- Revamping operations planning, sales and integrated business planning as customers resume their orders.

- Prioritizing according to product demand and profitability — consider customer preference.

- Building a model around the demand plan, risks, actions, issues and dependencies.

Suppliers and Sourcing

- Anticipating shortages of necessary materials or supplies.

- Updating supplier agreements, SLAs and schedules.

- Creating opportunities for strategic collaboration with major suppliers.

Inventory

- Inventory planning and replenishment strategy according to real-time demand.

- Building a multi-layer inventory model to purchase raw materials based on inventory planning.

- Setting up a system to monitor and manage inventory.

Workforce

- Collaborating with the HR department to identify hiring needs and roll out safety guidelines.

- Building responsive processes and staffing models to take on another potential wave of COVID-19.

- Implementing relevant technologies to track workers’ proximity, such as distance bracelets and contract tracing.

Production Assets

- Increasing efficiency of production/distribution centers and operational workflows.

- Tracking daily demand and supply needs to align production targets.

- Doing health checks for major production assets – accounting for current restrictions that affect travel, repair or maintenance.

Distribution and Logistics

- Pre-arranging secure transportation.

- Reviewing contracts for third-party providers — do they offer recovery support options and adjusted SLAs as needed?

- Reviewing logistics networks and trade routes for any backlog at ports.

Dan Weinberger is chief executive officer of Morpheus Network.