Think Tank

Four Tips for Complying with the Uyghur Forced Labor Prevention Act

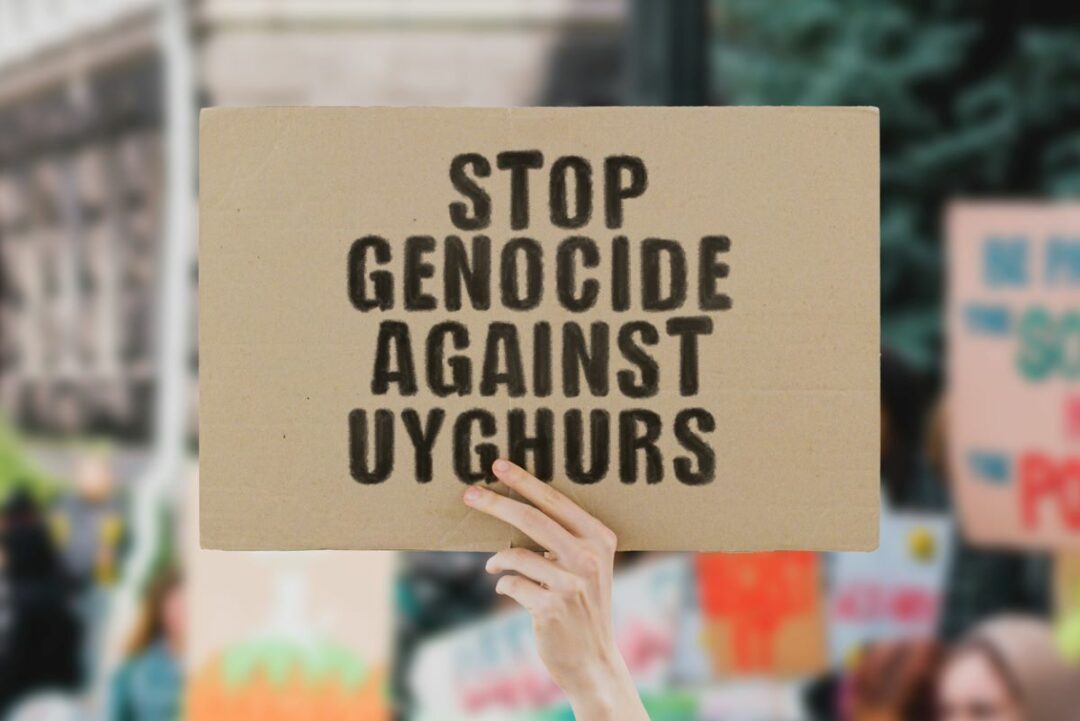

Photo: iStock.com/Andrii Koval

Forced labor has long plagued global supply chains, and continues to grow. Deeply embedded in the production and movement of goods around the world, it’s notoriously difficult to spot, much less eradicate.

The International Labor Organization estimates that nearly 50 million people are living under conditions of modern slavery. Of those, 28 million are working under forced labor conditions, including more than 3.3 million children. It’s a problem found at every stage of the supply chain, from workers made to harvest fields or mine metals, to those forced to make parts or assemble finished product on the factory floor. Exploitation even extends to the warehousing and shipping operations that connect each point in a supply chain.

While these human-rights violations exist nearly everywhere in the world, they are particularly prevalent in Asia and the Pacific region, where more than 11 million people are in forced working conditions. But the problem isn’t confined there. Goods produced across this region eventually make their way into the global marketplace. Businesses and consumers unknowingly (and sometimes knowingly) end up making purchases tainted by slave labor or child labor, which only fuels the vicious cycle.

What will it take to eradicate human rights violations in the supply chain? There’s no easy answer, but it will certainly require the combined efforts of governments around the world, as well as the cooperation of businesses that import from high-risk areas.

The U.S. government has recently taken strong steps with passage of the Uyghur Forced Labor Prevention Act (UFLPA). Signed into law by President Biden on December 23, 2021, it was designed to prevent goods made wholly or in part with forced labor in the Xinjiang region of China from entering the country.

Located in Northwest China, the Xinjiang Uyghur Autonomous Region is a massive territory that’s rich in natural resources. It supplies global supply chains with significant amounts of important industrial materials, as well as agricultural products, such as the polysilicon used in solar panels and cotton for Western apparel. The target list continues to grow as evidence is collected from third-party sources.

In recent years, the Chinese government has committed crimes against humanity, such as imprisonment, torture, surveillance and forced sterilization. These horrific acts target the Uyghur people, a predominantly Muslim ethnic minority, as well as members of other mostly Muslim communities in Xinjiang.

Since 2017, the Chinese government has detained more than a million Uyghurs in forced labor camps, while separating families and sending others to work in factories throughout the country. With forced labor so prevalent, it’s highly likely that any goods coming from the region are products of severe exploitation of the Uyghur people.

The U.S. has officially condemned China’s actions, and on June 21, 2022, U.S. Customs and Border Protection (CBP) began enforcing the UFLPA. As part of the act, the Forced Labor Enforcement Task Force (FLETF) developed and published the UFLPA Entity List, which identifies specific companies and products affiliated with forced labor in Xinjiang. The list includes four groups:

- Entities in Xinjiang that mine, produce, or manufacture wholly or in part any goods, wares, articles, and merchandise with forced labor;

- Entities that work with the government of Xinjiang to recruit, transport, transfer, harbor or receive forced labor;

- Entities that export products made by the groups listed above from China into the U.S., and

- Facilities and entities that source material from Xinjiang or from persons working with the government of Xinjiang for the purposes of any government-labor scheme.

CBP is working to identify any goods produced or exported by entities on this list, and then prevent their entry into the U.S. Any finished goods made by other manufacturers using inputs from entities on the ULFPA Entity List are also prohibited from entry.

Complying with the UFLPA might seem straightforward: If a product touches Xinjiang in any way, it can’t enter the U.S. Yet today’s supply chains are highly complex. Importers often struggle with limited visibility upstream, as well as inefficient supply chain practices within their own organizations, making it a big challenge to navigate regulatory requirements.

Following are four tips to help importers get on the right track towards compliance with the UFLPA

Know the rules. Essentially, UFLPA enforcement operates on the principle of “guilty until proven innocent.” The act establishes a rebuttable presumption that all goods mined, produced, or manufactured wholly or in part in Xinjiang, or by entities on the UFLPA entities list, are a product of forced labor, unless importers can prove otherwise.

When importing goods that fall under the scope of the UFLPA, businesses must provide documentation demonstrating that:

- The importer has complied with due diligence guidance set forth by the UFLPA;

- The importer has responded completely and substantively to all CBP requests for information, and

- The imports were not mined, produced or manufactured wholly or in part with forced labor

Alternately, importers may request an exemption backed by definitive evidence that their goods aren’t subject to the UFLPA.

By understanding and proactively compiling the evidence they’ll need, importers will be well-prepared to quickly respond to any UFLPA enforcement actions.

Know the risks. It’s important to know what’s at stake if a business is found in violation of the UFLPA. After all, understanding potential negative business impacts often spur company leaders to prioritize compliance.

If importers can’t provide the proper documentation, their shipments could be subject to seizure and forfeiture. Businesses found in violation of the UFPLA may also face severe civil and criminal penalties.

Beyond that, violators face even wider repercussions. Today’s consumers demand that companies take greater accountability for their social and environmental impacts, and any associations with forced labor is likely to cause major damage to a brand’s reputation.

Know your partners and products. Under the UFPLA, companies must conduct heightened due diligence to ensure they don’t work with any external partners or purchase any goods connected to forced labor. Since importers often only have visibility into their direct suppliers, these connections aren’t always obvious. For instance, an importer might know which country its direct suppliers source goods from, but not how or where that supplier produces its materials.

That’s why it is so critical for companies to establish a strong trade-compliance program. This should include conducting thorough supplier screenings and risk assessments, identifying and mitigating any existing violations as early as possible, and continuously monitoring for ongoing compliance.

Know how technology can help. CBP has announced plans to adopt enhanced supply-chain tracing technologies that support UFLPA enforcement. Likewise, importers should explore how technology can help their own organizations perform effective due diligence, minimize risk, and ensure that they have all the proper documentation to satisfy compliance requirements.

A valuable tool to consider is automated global trade compliance software. These software applications can ease the burden on importers by automating:

- Restricted party screening, ensuring any selected supply chain partners are low risk;

- Supplier relationship management, making it easy to improve supplier selection, monitor performance and organize all supplier compliance documentation;

- Import management, preventing costly delays and ensuring that goods quickly clear through CBP and other government agencies, and

- Global trade compliance analytics, generating real-time insights into compliance processing and helping businesses make fast, smart decisions to support overall trade compliance.

Regulatory requirements surrounding acts like the UFLPA aren’t written in stone. Rather, they are constantly evolving as geopolitical situations change, new information emerges, and new technology becomes available. It may feel overwhelming for importers trying to keep up with it all. But through heightened due diligence, a strong understanding of their supply chains, and the right supporting technology, importers can do their part in the fight to eradicate human rights violations around the globe.

Jerry Peck is vice president of product management with QAD.