Think Tank

Five Ways to Upgrade Your Business Planning Process With Advanced Analytics

Many of today’s supply chains will be unrecognizable by 2020.

There's no doubt that most companies could benefit from a quicker and smarter supply chain that automates routine, responds to event-based opportunities and mitigates risk and disruptions. But how do we get there from where we are today?

Enter advanced analytics.

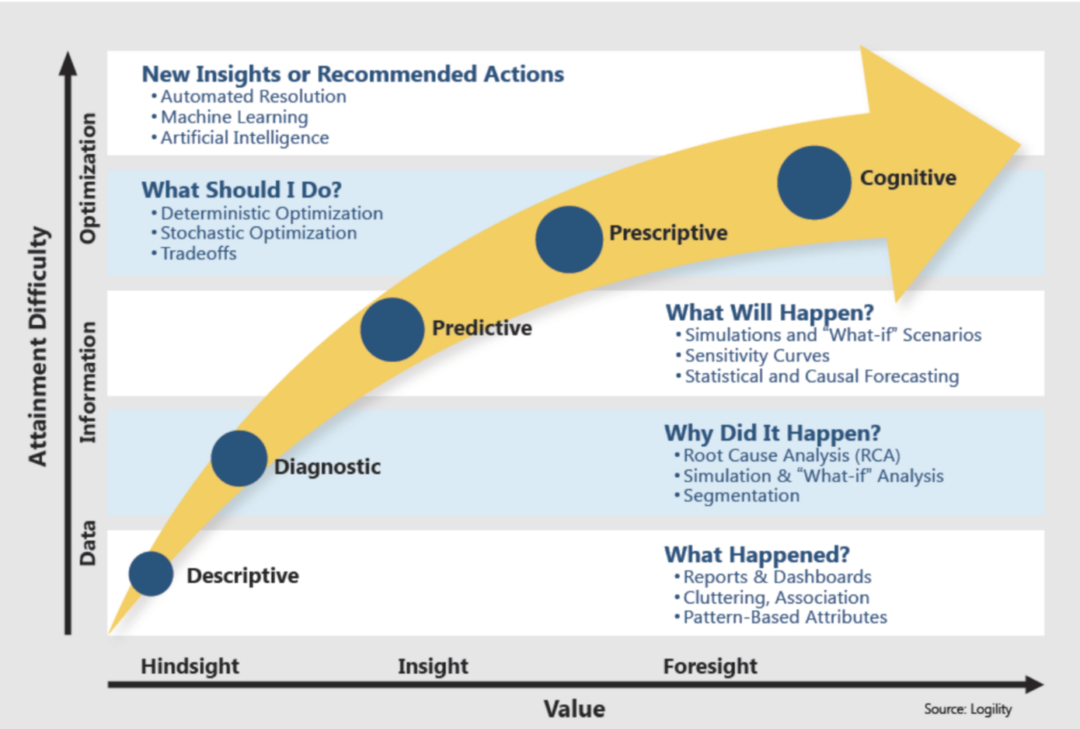

A sometimes-daunting endeavor, but at its root, analytics is simply the discipline that applies mathematics and logic to data — to then provide insights for decision making. There are five levels to this discipline, according to Gartner:

- Descriptive. Determine what happened through reports, key performance indicators, etc.

- Diagnostic. Figure out why it happened through root cause analysis, the application of 6-Sigma type tools, etc.

- Predictive. Determine what will happen from forecasts, what-if scenarios, simulations, etc.

- Prescriptive. Decide what should be done through algorithmic optimization. Optimization programs could provide advice to support human decisions or could be allowed to automatically take action.

- Cognitive. Derive new insights or recommended actions through artificial intelligence and machine learning.

Complexity grows as you move from “descriptive” to more advanced levels of analytics — but so does maturity and value. Higher levels (prescriptive, cognitive) will enable automated and smart supply chain operations. But the question still stands: How do we get there?

Most companies have a mid-term, tactical planning process — like sales and operations planning (S&OP), integrated business planning (IBP), etc. — that attempts to look into the future to balance supply and demand and meet financial objectives. It seems logical then to build on this planning process by incorporating advanced analytics. In fact, in a 2017 study by Ernst & Young and Forbes Insights, 57 percent of respondents said they leverage analytics in their S&OP processes. As supply chains become more connected and collaborative, we’ll see advanced analytics more and more in planning and synchronization.

Here are just a few examples of how advanced analytics could enhance your tactical planning process — and enable a more automated and intelligent supply chain.

Supply Chain Network Simulation

Simulating the supply chain can often provide unique insights. From a display of the full, end-to-end supply chain — or just a segment — you can derive critical information needed to conduct robust analysis. A network simulator can actively display demand projections, facility and lane capacities, and other user-defined information for a selected time horizon. Additionally, network simulations can visually highlight areas to quickly draw the planner’s attention to opportunities and risks — and provide drill-down capabilities for root-cause analysis.

Segmentation

Numerical and visual segmentation is a powerful application of diagnostic analytics that can provide insights into the operation of your supply chain. For example, a visual segmentation by product group, revenue and margin can help determine which product groups represent your top/bottom volume or margin producers. This type of analysis provides insight for product rationalization, price adjustment and sales and marketing initiatives.

Heat Maps

Heat map displays are another form of diagnostic analytics that enable rich analysis of complex data. At a glance, you are able to discern areas of concern based on color, size or position of a specific grouping of information.

For example, a heat map displaying total revenue (represented by the size of the box) and forecast accuracy (represented by the color of the box) by sales region will quickly identify which sales regions might warrant additional analysis — such as those with high volume and low forecast accuracy. The next logical step would be to conduct a root-cause analysis to determine exactly what product groups and specific products are causing the high forecast error situation.

What-If Scenarios

One of the most powerful advanced analytics techniques is the use of multiple “what-if” scenarios to determine an appropriate response to a planned or unplanned supply chain event. To be effective, these scenarios must be easy to set up, intuitive and simple to run and modify.

For example, a “what-if” scenario could be set up to look at an upcoming promotional event to analyze various price and lift combinations and their effects on promotion profitability. Each scenario would include a baseline forecast, a projected promotional lift, critical resource capacities and the corresponding revenue and margin produced.

A number of insights are quickly visible by displaying side-by-side scenarios that contain both financial and volumetric information. If there’s an increase in promotional volume, one would expect a corresponding increase in revenue. But is there enough manufacturing and distribution capacity to handle the volume growth? Can we obtain enough raw materials to support the promotion? Which promotion scenario produces the best margin? Any number of questions can be answered using multiple “what-if” scenarios, depending on the information displayed.

Algorithmic Optimization

Algorithmic optimization enables some of the most advanced examples of predictive and prescriptive analytics today. Systems provide recommended actions and, if desired, the system can be enabled to automate the optimal decision. Examples of algorithmic optimization used in the supply chain include:

- Inventory optimization

- Advanced production and scheduling

- Supply optimization

- Transportation load and route optimization

- Optimized selection and application of demand planning algorithms

What analytical tools is your company using to help transform its supply chain? In what other areas of the supply chain can these tools be used to enhance capabilities?

Henry Canitz is director of product marketing and business development for Logility.