Think Tank

How Automation Can Help FMCG Supply Chains Weather the Storm

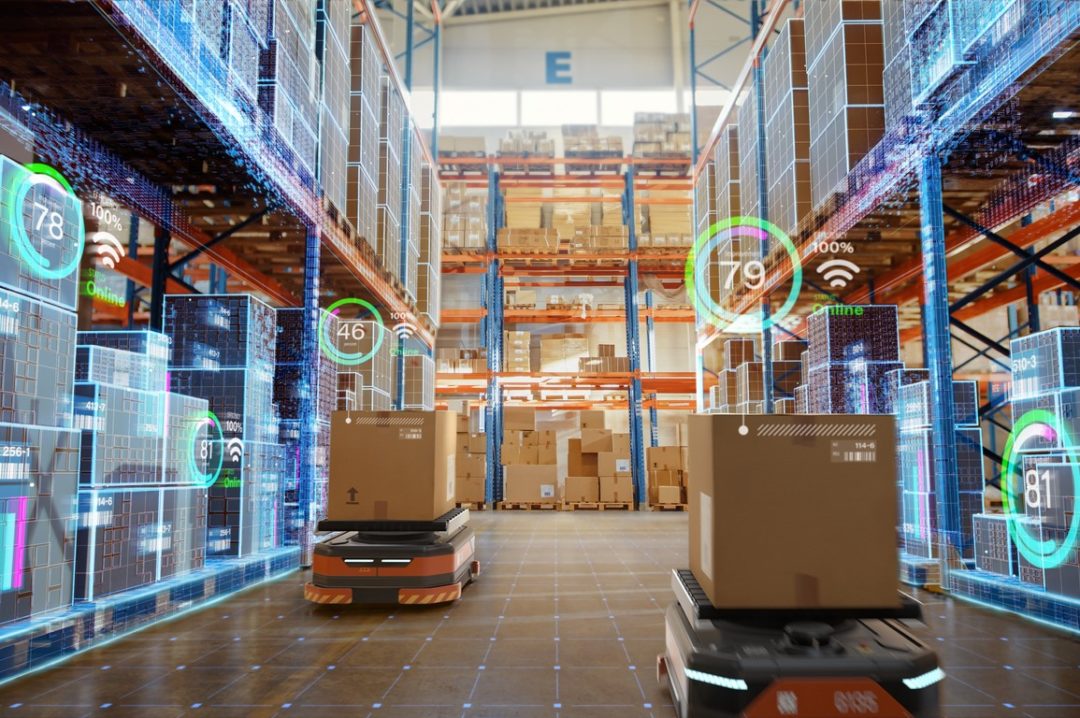

Photo: iStock.com/gorodenkoff

Fast-moving consumer goods (FMCG) supply chains continue to find themselves dealing with both labor shortages and external pressures due to global disruptions. According to KPMG, more than six out of 10 global organizations expect geopolitical instability to have a detrimental impact on their supply chains in the next three years.

To counter these impacts and weather the storm of volatility, many FMCG organizations are turning to technology to streamline operations within their supply chains, and maximize the cost savings gained from improvements in efficiency and collaboration. For manufacturing supply chains in particular, the integration of robotics and process automation presents an opportunity to tackle many of the critical issues they currently face.

Following are three issues threatening external manufacturing supply chains, as well as ways in which physical and digital automation tools can improve them.

Labor Constraints

The FMCG industry is grappling with a shortage of labor needed for external supply chain partners, such as contract manufacturers and co-packers, to manage production and fulfill orders.

To address this crunch, suppliers are turning to systems for improving the visibility and speed of data flow on the production floor, as well as robotic automation tools to enhance the capabilities of existing staff.

Tasks that were once dependent on humans can now be seamlessly executed by automation with speed, precision and efficiency. In some cases, both robotics and data automation systems can be implemented at a modular scale, speeding up implementation and time to value for production lines.

Market Volatility

Data continues to be the fuel that enables effective supply chains, and the enablement of near real-time data visibility is a strength that many FMCG manufacturing supply chain networks have yet to fully exploit.

With the help of a supply chain collaboration tool that centralizes communication and data flow between manufacturers and their external supply chain partners, all parties can realize improved responsiveness and effectiveness. Large manufacturers’ supply chain planners can manage order capacity and fulfillment with greater accuracy, while external suppliers can respond more effectively to sudden demand and inventory changes.

Additionally, by analyzing historical data and real-time market trends, supply chain planners can improve demand forecasting, anticipate potential supply disruptions and adjust their strategies accordingly. This preemptive stance enables organizations to optimize inventory levels, enhance production planning and ultimately minimize the impact of unforeseen challenges.

Data Silos

Many supplier relationships are tenuously managed by a mishmash of phone calls, e-mails and file attachments. Given the speed of today’s market, this asynchronous framework is likely to cause delays, errors and increased cost due to miscommunication.

Improved data flow results from the use of a supplier collaboration tool. It allows all partners — brand manufacturers, co-packers, contract manufacturers, raw ingredient and packaging suppliers — to draw data from the same source, dispelling confusion and opening up opportunities for enhanced collaboration. The result is streamlined coordination among suppliers, distributors and manufacturers, and a synchronized ecosystem.

According to a KPMG survey, six in 10 companies plan to invest in digital technology to bolster their supply chain processes, data synthesis and analysis capabilities.

With a centralized platform for information exchange and real-time updates, supply chain partners can swiftly adapt to changes, identify potential bottlenecks and implement agile solutions, fortifying the resilience of the entire supply chain network.

FMCG supply chains can no longer afford to ignore the agility, efficiency and competitive edge that digital and physical automation offers. The shop floor efficiencies of robotics and process automation, combined with the benefits gained by planners on the manufacturing side, offer a new way for companies to operate with greater efficiency, accuracy, and adaptability amid the constraints and volatility of today’s consumer market.

Christine Barnhart is chief marketing and industry officer with Nulogy.